The Most Popular Twisted Macro-Synthetic Fiber

- Home

- /

- Fiber Types

- /

- Twisted Macro Synthetic Fiber

Quality Twisted Macro-Synthetic Fiber

The Tenabrix manufacturer’s unique production process results in superior twisted macro-synthetic fiber quality.

Tenabrix twisted macro-synthetic fiber plays an irreplaceable role in concrete applications.In particular, it shows excellent performance in durability, crack resistance and toughness.

- Twisted Macro-Synthetic Fiber Price:Negotiable

- Custom Service:Length,Color,Package

- MOQ:1,000kgs

- Shipping:7-10 days for delivery from factory

What is Twisted Macro-Synthetic Fiber?

TenaBrix® Twisted Macro Synthetic Fiber is a high-performance fiber composed of a blend of polypropylene and polyethylene resins, specifically engineered to enhance the durability and performance of conventional concrete, pre-cast concrete, and shotcrete.

Its unique twisted bundle design creates a strong mechanical bond with the concrete matrix, providing tensile and bending properties comparable to traditional steel reinforcement. This innovative fiber significantly improves crack resistance and toughness, making it an ideal replacement for steel fibers in fiber-reinforced concrete, while optimizing the overall structural integrity of the material.

Specifications and Characteristics

| Fiber Type | Twisted, Macro-Synthetic Fiber |

| Brand | TenaBrix® |

| Raw Material | Polypropylene/polyethylene |

| Color | Gray |

| Length | 38mm, 48mm, 50mm,54mm |

| Tensile Strength | ≥480MPa |

| Elastic Modulus | ≥4000 MPa |

| Specific Gravity | 0.91/ cm3 |

| Alkali, Salt, and Acid Resistance | Excellent |

| Melting Point | 160 °C |

| Water Absorption | Nil |

| Electrical/Thermal Conductivity | Low |

Excellent performance

Superior Crack Control

Distributes stress more evenly throughout the concrete, effectively controlling cracks caused by shrinkage, temperature fluctuations or load stresses and preventing large cracks from forming.

Enhanced Toughness

These fibers bridge cracks, providing additional support, allowing the concrete to absorb more energy before failure, which significantly improves the toughness of the concrete.

Excellent Corrosion Resistance

Twisted Macro-Synthetic Fiber is unlike with traditional steel fiber, synthetic fibers do not corrode, making them especially suitable for use in corrosive environments.

Reduced Construction Costs

Compared to traditional rebar placement, twisted macro-synthetic fibers are easier to mix into concrete, significantly reducing construction time and labor costs.

Why Choose Tenabrix Twisted Macro-Synthetic Fiber?

-

Durable and Long-Lasting Unlike steel fibers that can rust, synthetic fibers ensure long-lasting performance with minimal maintenance.

-

Versatile Applications Performs exceptionally well in extreme temperatures and moist environments, making it a versatile choice for various concrete applications.

-

Easy to Use Highly compatible with concrete, making the construction process simpler and faster, saving time and labor.

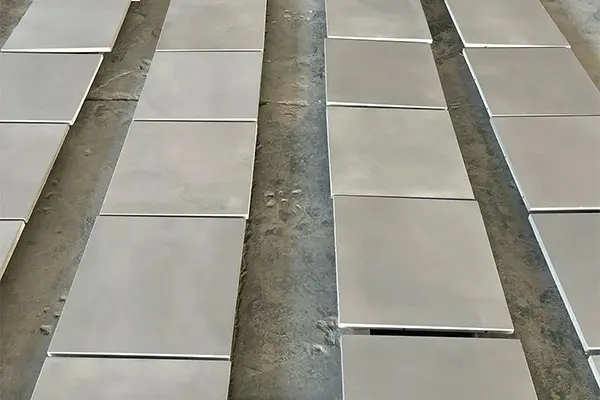

Twisted Macro-Synthetic Fiber had shown excellent performance in multiple applications

Industrial Floor

Concrete Pavement

Shotcrete Tunnel

Slabs-on-Ground

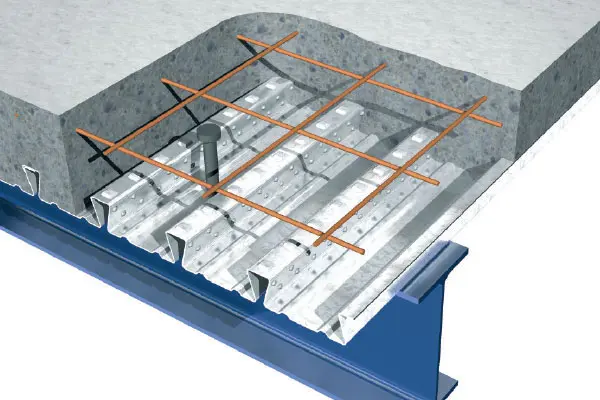

Composite Metal Decks

Bridge Decks

Specifications / Compliances

ASTM C1116-03, Standard Specification for Fiber-Reinforced Concrete and Shotcrete (Type III)

ASTM D7508/D7508M-20, Standard Specification for Polyolefin Chopped Strands for Use in Concrete

ACI 360 R-10, Guide for Slabs-On-Ground

The Best Supplier and Partner-Tenabrix

With limited professional suppliers of polypropylene fibers in China, Tenabrix stands out as a leading provider of high-quality concrete additives. Here’s why distributors and buyers trust us.

As the world’s leading supplier of concrete fibers. Tenabrix™ fibers are manufactured in strict accordance with B/T19001-2016/ISO9001 standards.

And it can be tested and evaluated by ASTM, CABO, ICBO and other organizations in the United States.

Reliable Quality

We are committed to delivering consistently high-quality fibers, ensuring that our clients can depend on us for every project.

Sustainable Solutions

Our water-soluble packaging not only makes fiber application easier but also reduces the environmental impact of plastic waste, supporting more sustainable construction practices.

On-time Delivery

We understand the importance of timelines in construction projects. With Tenabrix, you can count on timely and efficient delivery to meet your project schedules.

Competitive Pricing

Get access to premium polypropylene microfiber at highly competitive prices. We ensure you receive excellent value for your investment.