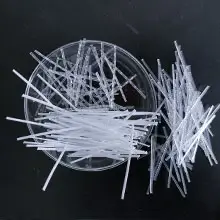

Polypropylene fiber (PP fiber) is a synthetic fiber made from the polymer polypropylene. PP fibers are used in a wide range of applications due to their strength, durability, and resistance to chemicals and heat.

There are several types of polypropylene fiber available in the market today. Each type has unique properties and is designed for specific applications. The most common types of polypropylene fiber used in concrete reinforcement include:

- Monofilament Fiber: Monofilament polypropylene fiber is a single, continuous strand of fiber that is added to concrete to improve its strength and durability. It is commonly used in non-structural applications, such as sidewalks, driveways, and patios.

- Fibrillated Fiber: Fibrillated polypropylene fiber is made up of multiple strands of fibers that are twisted together to form a rope-like structure. This type of fiber is used in more demanding applications, such as industrial flooring and concrete slabs.

- Macro Synthetic Fiber: Macro synthetic polypropylene fiber is a high-strength fiber that is designed to replace traditional steel reinforcement in concrete. It is used in applications where high tensile strength is required, such as bridge decks and precast concrete products.

Advantages of Polypropylene Fiber:

Polypropylene fiber offers several advantages over traditional concrete reinforcement materials, such as steel. Some of the key advantages of polypropylene fiber include:

- Increased Durability: Polypropylene fiber improves the durability of concrete by reducing cracking and increasing its resistance to freeze-thaw cycles.

- Improved Workability: Polypropylene fiber makes concrete easier to work with by reducing the amount of water required in the mix. This results in a more workable mix that is easier to place and finish.

- Corrosion Resistance: Unlike steel reinforcement, polypropylene fiber does not corrode over time. This means that it will not rust or degrade, which can lead to structural damage.

- Reduced Cost: Polypropylene fiber is generally less expensive than traditional reinforcement materials, such as steel. This can result in significant cost savings for large-scale construction projects.

- Easy to Install: Polypropylene fiber is easy to install and can be added directly to the concrete mix during batching. This means that it does not require any special equipment or training to use.

Applications of Polypropylene Fiber:

Polypropylene fiber is used in a wide range of concrete applications, including:

- Residential Concrete: Polypropylene fiber is commonly used in residential concrete applications, such as driveways, patios, and sidewalks.

- Industrial Flooring: Polypropylene fiber is used in industrial flooring applications, such as warehouses, factories, and commercial kitchens.

- Precast Concrete: Polypropylene fiber is used in precast concrete products, such as septic tanks, utility vaults, and retaining walls.

- Bridge Decks: Polypropylene fiber is used in bridge decks to improve their durability and resistance to wear and tear.

- Shotcrete: Polypropylene fiber is used in shotcrete applications, such as tunnel linings and slope stabilization.

Conclusion

In conclusion, polypropylene fiber is a versatile and cost-effective material that offers several advantages over traditional concrete reinforcement materials. Its unique properties make it ideal for a wide range of concrete applications, from residential driveways to large-scale.