Fiber mesh concrete, also known as fiber-reinforced concrete, presents a compelling alternative to traditional steel-reinforced concrete. By incorporating various types of fibers into the concrete mix, this innovative construction material offers a range of benefits and considerations for diverse applications.

1. What Does Fiber Mesh Do For Concrete?

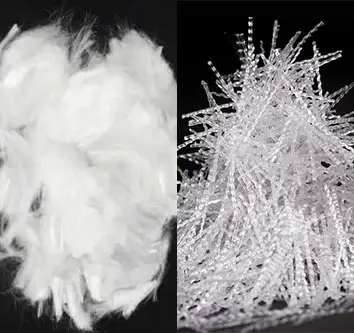

Fiber mesh concrete involves the integration of fibers into the concrete mix at the job site. These fibers, categorized as microfibers and macrofibers, contribute to the concrete’s overall performance and durability.

1.1 Does Fiber Mesh Add Strength to Concrete?

While concrete boasts impressive compressive strength, its tensile strength is comparatively lower. Macrofibers, up to 50mm in length, significantly enhance the concrete’s flexural and tensile strength. Their profile, whether metallic or synthetic, allows the concrete to grip onto the fibers during the hardening process, effectively preventing crack propagation.

1.2 What Types Of Fibers Are Used in Concrete?

Microfibers, less than 10mm in length, minimize bleeding in fresh concrete, reducing the likelihood of hairline cracks. Macrofibers, on the other hand, enhance tensile strength and can be made of metals or synthetic polymers. Synthetic fibers, known for their strength and corrosion resistance, are becoming increasingly popular.

2. Fiber Mesh Concrete Pros And Cons

2.1 Advantages of Fiber Reinforced Concrete

- Reduced Shrinkage and Cracking: Fiber mesh helps mitigate shrinkage and cracking in concrete structures.

- Improved Tensile Strength: Similar to traditional reinforced concrete, fiber-reinforced concrete enhances tensile strength.

- Spalling Prevention: The melting of fibers within the concrete allows for escaping water content, reducing the chance of spalling.

- Ease of Inclusion: Incorporating fibers into the concrete mix is straightforward.

- Corrosion Resistance: Polymer fiber reinforcement provides better corrosion resistance than steel.

2.2 Disadvantages

- Clumping: Steel fibers may clump in ready-mix trucks, leading to uneven distribution during pouring.

- Cost: Fiber mesh concrete can be more expensive than traditional rebar and wire-mesh concrete.

2.3 Fibre Mesh Concrete vs Rebar

Fiber mesh concrete offers advantages in terms of ease of use, time efficiency, and space savings compared to traditional steel-reinforced concrete. The fibers, added to the mix during the concrete truck’s mixing process, disperse uniformly without the need for on-site storage or complex setup.

2.4 Should I Put Fiber in My Concrete?

Fiber mesh concrete proves to be a versatile and user-friendly option, especially in floor slab applications where it can replace steel-reinforced concrete. The key lies in selecting the appropriate fibers for each application, considering factors such as micro versus macro fibers and the choice between steel and synthetic materials.

Fiber mesh concrete stands as a promising solution to enhance the performance of concrete structures, offering a range of benefits from improved tensile strength to corrosion resistance. As with any construction material, careful consideration of the specific application and choice of fibers is crucial to maximize the advantages of fiber-reinforced concrete.