Concrete is one of the most widely used materials in construction. Its strength, durability, and versatility make it ideal for everything from residential driveways to industrial floors. However, on its own, concrete has one big limitation: it’s strong in compression but weak in tension. That’s why reinforcement is so important. Two of the most common reinforcement options are wire mesh and fiber mesh.

If you’re trying to decide between fiber and wire mesh for your next project, this guide breaks down the advantages, drawbacks, and key considerations of each method to help you make the best choice.

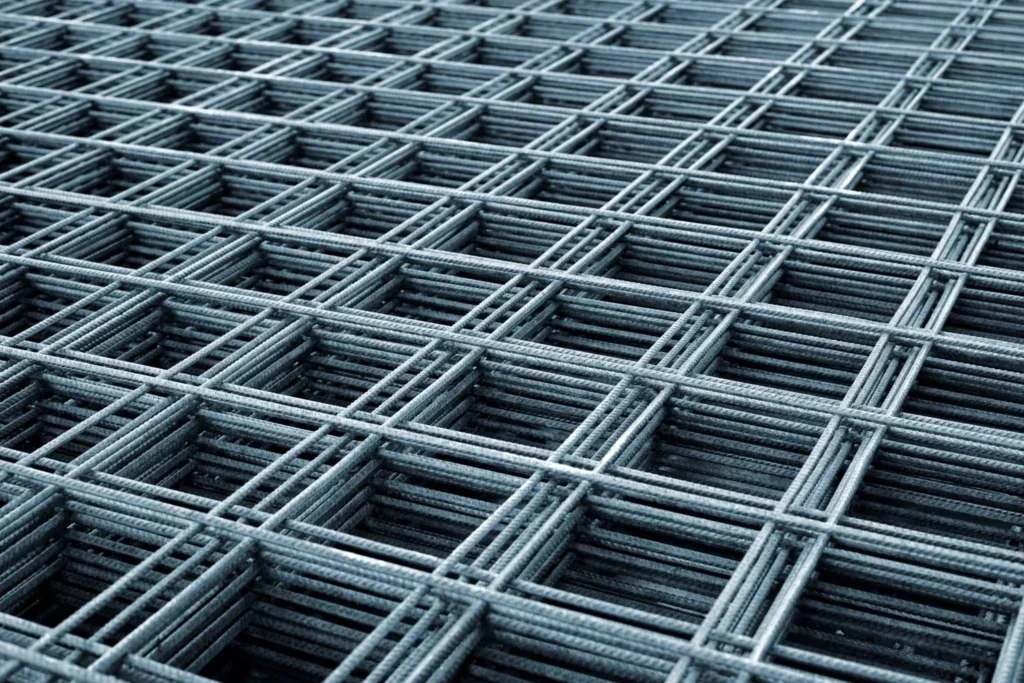

What Is Wire Mesh in Concrete?

Wire mesh, also called welded wire fabric, consists of longitudinal and transverse steel wires arranged in a grid pattern. The mesh can be welded or woven and is placed inside the concrete slab before pouring.

It’s widely used in construction because of its straightforward design and proven track record for adding tensile strength to concrete structures.

Advantages of Wire Mesh

Wire mesh has been the go-to reinforcement for decades. Here’s why it’s still a trusted option today:

Strength and Stability

Wire mesh provides excellent tensile strength and helps distribute loads evenly across a slab. This improves the structural integrity of the concrete, reducing the likelihood of large cracks or failure under pressure.

Versatility

It can be easily customized for various applications—such as driveways, sidewalks, foundations, and even precast panels. The ability to cut or adjust the mesh on-site makes it convenient for projects of different shapes and sizes.

Cost-Effectiveness

For many projects, wire mesh remains one of the most affordable reinforcement solutions. Combined with its familiarity in the industry, this makes it a go-to option for contractors.

Corrosion Resistance (Optional)

Stainless steel wire mesh or coated variants offer high resistance to corrosion, which can extend the lifespan of the reinforcement in environments exposed to moisture or chemicals.

Considerations When Using Wire Mesh

- Installation Accuracy Matters For wire mesh to work effectively, it must be placed at the correct depth and position within the concrete slab. If it shifts during pouring, its reinforcing capabilities can be compromised.

- Labor-Intensive Installing wire mesh takes time and requires careful handling, which can increase labor costs on large or complex projects.

- Limited Crack Control at Surface Level While wire mesh strengthens concrete overall, it may not prevent micro-cracking at the surface caused by shrinkage during curing.

What Is Fiber Mesh in Concrete?

Fiber mesh is a newer alternative to traditional reinforcement methods. Instead of placing steel mesh within the slab, short, discrete fibers are mixed directly into the concrete before it’s poured.

These fibers—commonly made from synthetic materials like polypropylene, nylon, or polyester—are dispersed throughout the mix to provide reinforcement in all directions.

Advantages of Fiber Mesh

Fiber mesh is quickly becoming popular thanks to its ease of use and performance benefits:

Enhanced Crack Control

Fibers work at the micro-level to reduce plastic shrinkage and drying shrinkage cracks, which commonly occur as concrete cures. This leads to a smoother, more durable finish.

Uniform Reinforcement

Because the fibers are distributed throughout the concrete, the reinforcement is more uniform compared to wire mesh. This is especially beneficial for preventing cracks in thin sections or irregularly shaped pours.

Improved Durability

Certain fiber types, like polypropylene, also increase the flexural strength of the concrete, making it more resistant to impact, abrasion, and fatigue over time.

Chemical and Corrosion Resistance

Synthetic fibers don’t rust and can withstand exposure to alkalis, salts, and other chemicals, making them ideal for harsh environments like industrial plants or coastal areas.

Faster Installation

Since fibers are added directly into the mix, there’s no need for placing or tying steel mesh, which can save time and reduce labor costs.

Considerations When Using Fiber Mesh

Fiber mesh also has its limitations, particularly for heavy-duty applications:

Not Always Suitable for Heavy Loads

While fiber mesh enhances crack control, it may not replace the structural load-bearing capacity of steel reinforcement in high-stress applications like bridge decks or heavy industrial floors.

Proper Mixing Required

To achieve uniform fiber distribution, the concrete must be thoroughly mixed. Poor mixing can lead to clumping or inconsistent reinforcement.

Higher Material Cost

In some cases, fiber mesh can be more expensive than traditional wire mesh upfront, though savings on labor and reduced cracking may offset the cost over time.

Fiber vs Wire Mesh in Concrete: Key Considerations

Choosing between fiber mesh and wire mesh isn’t about which one is “better” overall—it’s about which is better for your specific project. Here are some key factors to guide your decision:

1. Project Scope and Application

- Wire Mesh is ideal for structural applications that require added tensile strength, such as driveways, sidewalks, foundations, and slabs with heavy loads.

- Fiber Mesh works best for applications where shrinkage cracking and surface durability are top concerns, such as thin overlays, decorative concrete, or residential slabs.

2. Cost and Labor

- Wire Mesh often has a lower material cost but may require more time and labor for proper placement.

- Fiber Mesh may have a higher upfront cost but reduces installation time and labor expenses because it’s added directly to the mix.

3. Performance Requirements

- If your project involves high load-bearing capacity, wire mesh or even rebar may still be necessary.

- If your priority is crack control and surface finish, fiber mesh provides excellent results.

- For some projects, a combination of both fiber and wire mesh is used to maximize benefits.

4. Environmental Conditions

- Wire Mesh made from standard steel can corrode if exposed to moisture or chemicals unless coated or stainless steel is used.

- Fiber Mesh is resistant to corrosion and chemicals, making it a better choice for aggressive environments.

Fiber vs Wire Mesh: Side-by-Side Comparison

| Feature | Wire Mesh | Fiber Mesh |

|---|---|---|

| Material | Steel wires (welded or woven) | Synthetic fibers (polypropylene, nylon, etc.) |

| Placement | Laid in the slab before pouring | Mixed directly into the concrete |

| Crack Control | Reduces large cracks, but limited at surface | Excellent for micro-crack and shrinkage control |

| Load-Bearing Capacity | High tensile strength, better for heavy loads | Limited structural capacity |

| Installation Time | Longer due to placement and tying | Faster (no placement required) |

| Corrosion Resistance | Prone to rust unless coated/stainless | Naturally corrosion-resistant |

| Cost | Lower material cost, higher labor | Higher material cost, lower labor |

Making the Right Choice for Your Project

Both fiber mesh and wire mesh offer unique benefits. The decision ultimately depends on your project’s size, budget, and performance needs. In many cases, contractors and engineers use fiber mesh for its crack control and ease of installation, while relying on wire mesh or rebar for heavy structural loads.

If you’re unsure, feel free to contact our expert team. They can assess the requirements and recommend the best reinforcement solution—or even a combination of both—for optimal results.

Conclusion: Fiber vs Wire Mesh in Concrete

When it comes to fiber vs wire mesh in concrete, there’s no one-size-fits-all answer. Wire mesh delivers time-tested strength and structural reinforcement, while fiber mesh excels at controlling shrinkage cracks and improving surface durability. By understanding the advantages and considerations of each, you can choose the reinforcement that ensures your concrete structure stands the test of time.