Steel fiber reinforced concrete (SFRC) is widely used in industrial floors, tunnels, precast elements, and other structures where crack control and toughness are important.

Among many design factors, one detail is often overlooked but plays a key role:

the number of end hooks on steel fibers.

In this article, we explain — in simple engineering terms — how different end hook designs influence performance, and how to choose the right option for your project.

Why Do Steel Fibers Have End Hooks?

Concrete is strong in compression but weak in tension. Once cracks form, they can grow quickly and reduce structural performance.

The primary function of steel fibers within concrete is to span cracks during their formation and propagation while transferring tensile stress, thereby limiting crack development.

Steel fibers help by:

Bridging cracks

Transferring tensile stress across cracks

Improving toughness and post-crack behavior

Compared with straight fibers, hooked-end steel fibers provide mechanical anchorage.

This anchorage helps prevent fibers from being pulled out when cracks open.

In simple terms:

End hooks help steel fibers “grip” the concrete more effectively.

How End Hook Number Influences Anchorage

From an engineering perspective, fiber pull-out resistance comes from two mechanisms:

- Friction between the fiber and concrete

- Mechanical anchorage created by the end hooks

When the number of end hooks increases:

- The resistance against fiber pull-out generally increases

- Fibers can continue carrying load even after cracks form

This is why multi-hook fibers are commonly used in applications requiring better crack control and toughness.

Effect on Compressive Strength: Limited Influence

Compressive strength is mainly controlled by the concrete matrix itself.

In practical engineering understanding:

- The number of end hooks does not significantly affect compressive strength

- Steel fibers mainly contribute to tensile behavior, crack control, and ductility

Therefore, end hook design should not be selected based on compressive strength alone.

Effect on Crack Control and Post-Crack Performance

The most important impact of end hook number appears after cracking.

When cracks open:

- Steel fibers bridge the crack

- End hooks resist pull-out

- Load can still be transferred across the crack

In general engineering practice:

- More end hooks provide more stable anchorage

- This helps maintain residual strength and deformation capacity

- Structures fail more gradually instead of suddenly

This behavior is especially valuable in:

- Industrial floors

- Tunnel linings

- Shotcrete applications

- Structures requiring high safety margins

More End Hooks ≠ Always Better

While increasing the number of end hooks improves anchorage, it also introduces trade-offs:

- More complex fiber shape

- More difficult fiber dispersion

- Potential impact on workability

- Higher material cost

Because of this, end hook design should be matched to the application, not maximized without consideration.

Practical Selection Guide for Steel Fiber End Hooks

Based on engineering principles and industry experience:

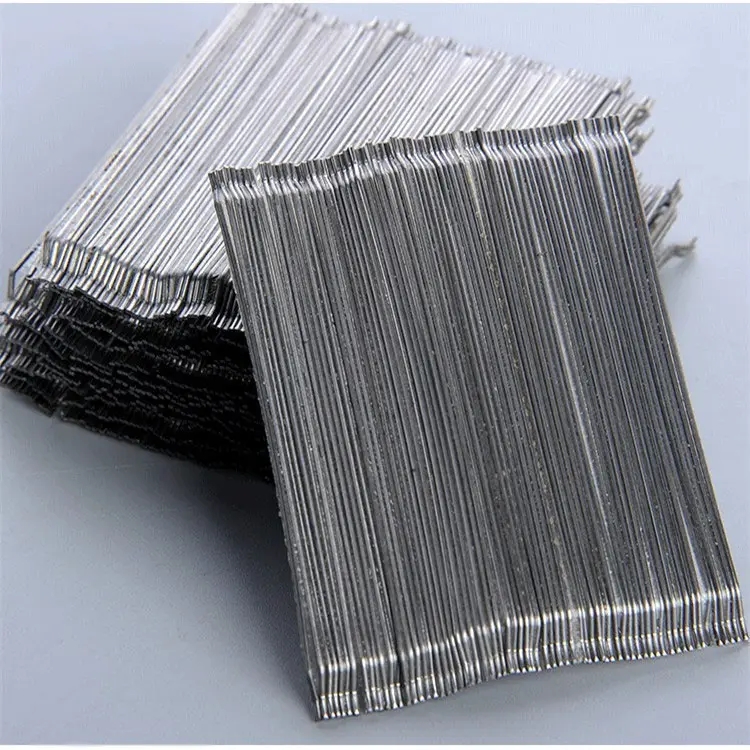

Single Hook Steel Fiber

- Suitable for cost-sensitive projects

- Moderate crack control requirements

- Easier dispersion and mixing

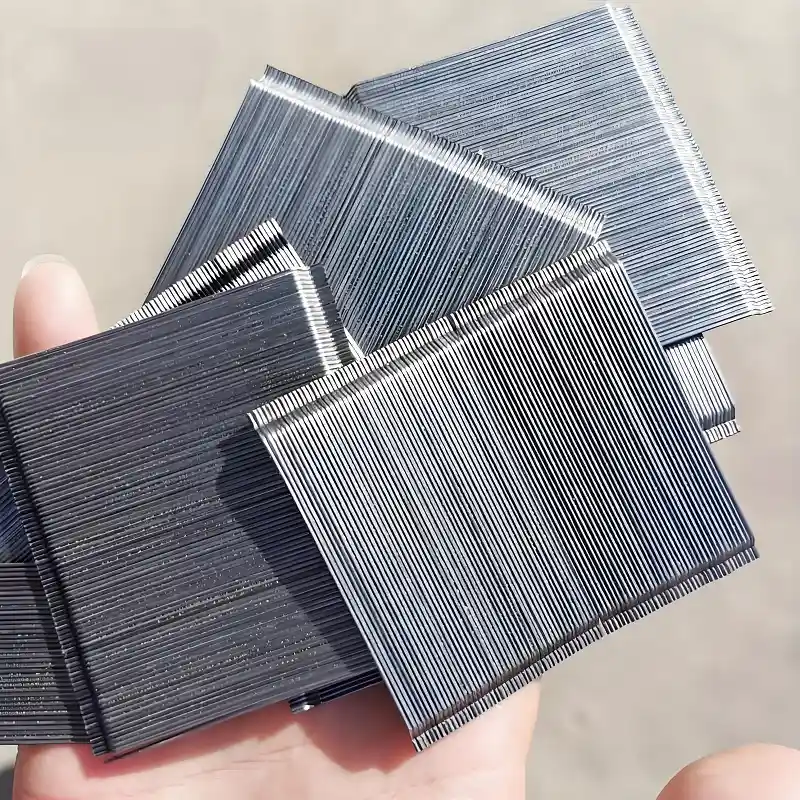

Double Hook Steel Fiber

- Balanced anchorage and workability

- Suitable for most standard SFRC applications

- Widely used in industrial and infrastructure projects

Multi-Hook Steel Fiber

- Strong anchorage and post-crack performance

- Recommended for high-toughness or high-safety structures

- Requires good mixing control and proper design

Conclusion: Choose Based on Application, Not Just Shape

The number of end hooks on steel fibers directly affects anchorage behavior and crack performance — but there is no universal “best” option.

The right choice depends on:

- Structural requirements

- Crack control and toughness needs

- Construction conditions

- Cost considerations

By understanding how end hook design works, engineers and buyers can make more informed and reliable material selections.

If you need support in selecting the right steel fiber for your project, feel free to contact us for technical guidance.