Concrete cracks are a prevalent issue in building structures, primarily caused by various internal and external factors leading to physical changes in concrete. These changes subsequently affect the stability and durability of the structures. Below, we will introduce the common types of concrete cracks and their underlying causes.

1. Plastic Settlement Cracks

These typically occur during or after the concrete pouring process, before the concrete reaches its initial set. They arise because the aggregates in the concrete mixture slowly settle under their weight, causing water to rise, a phenomenon known as bleeding. In plain concrete, internal settling is uniform.

However, in reinforced concrete, the concrete settles beneath the steel reinforcement, resulting in cracks along the surface of the reinforcement. This type of plastic settlement crack is particularly severe in highly workable concrete or concrete with a high water-to-cement ratio.

Characteristics: Cracks appear parallel to the steel reinforcement.

2. Plastic Shrinkage (Drying) Cracks

These cracks form when the concrete is still in its plastic state after pouring. They are triggered by factors such as hot weather, high evaporation rates, strong winds, or the concrete’s high heat of hydration.

Characteristics: They typically exhibit two shapes: irregular turtle-like or radial cracks, or intermittent cracks spaced at intervals on the concrete surface.

3. Temperature-Related Cracks

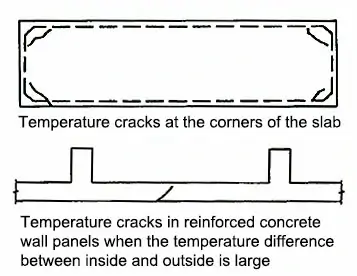

Changes in external temperature cause concrete to expand and contract, resulting in temperature-related cracks. When constrained, concrete develops internal stress. If this stress surpasses the concrete’s tensile strength limit, temperature-related cracks form.

Characteristics: The shape and occurrence of temperature-related cracks vary significantly based on factors such as temperature distribution, temperature differentials, constraint levels, and structural component types. Over time, these cracks may gradually widen and worsen, making temperature-related cracks among the most complex types of concrete cracks.

4. Heat of Hydration Cracks

These cracks are often observed during the construction of large-volume or high-strength concrete due to the significant heat generated during the hydration process. The substantial temperature difference between the interior and surface of the concrete, coupled with the external environment, results in thermal stress and subsequent cracks.

Characteristics: These cracks may include surface cracks, internal cracks, bottom cracks, penetrating and non-penetrating cracks, as well as cracks concentrated at corners, abrupt changes in cross-sections, and void corners. In terms of shape, they can be turtle-like or radial cracks, horizontal cracks, vertical cracks, or diagonal cracks.

5. Foundation Settlement Cracks

In most cases, structures with high stiffness in their main concrete body and foundation have better resistance to foundation settlement. However, inadequate foundation treatment, especially on poor soil like expansive clay, freeze-thaw soil, expansive soil, saline soil, or weak soil, can lead to foundation settlement (swelling) cracks.

Characteristics: Foundation settlement cracks often exhibit a pattern of heavier lower sections and lighter upper sections, with an emphasis on diagonal cracks, and occasionally vertical and horizontal cracks. These cracks tend to first appear on concrete beams or at beam-column intersections. In cases of high structural stiffness, horizontal cracks might also manifest at the intersection of independent foundations and columns.

6. Stress Concentration Cracks

Stress concentration cracks usually emerge after the primary structure has been constructed. They are primarily found at openings such as doors and windows, areas with sudden changes in structural stiffness, structural openings, and locations with abrupt changes in structural rigidity, as well as points where concentrated loads are applied.

In the case of prestressed reinforced concrete structures, these cracks often form at localized compressive stress points where the reinforcement is anchored.

Characteristics: Stress concentration cracks tend to develop at corners of door and window openings or at the corners of projections in flat or vertical surfaces, often assuming a diagonal, wedge-shaped appearance. Locations subjected to significant concentrated loads might experience splitting-type cracks. In some instances, localized compressive stress at anchorage points in prestressed structures results in the emergence of one or several cracks, often radiating outward.

When confronted with these concrete crack issues, Tenabrix Concrete Fiber emerges as a robust solution. By incorporating materials such as Tenabrix Concrete Fiber, it is possible to effectively enhance concrete performance, reducing the occurrence of crack problems, and ultimately extending the lifespan of buildings while ensuring structural integrity.

TenaBrix is a leading professional concrete fiber manufacturer in China. Our manufacturing plant with an annual production capacity of 50000MT.Invest in Tenabrix Concrete Fiber to enhance your concrete structures’ durability and safety. Contact us to learn more about how our solutions can benefit your construction projects.