As a reinforcement material for engineering, polypropylene fiber is becoming more and more popular in the construction industry. The most commonly used are Polypropylene synthetic microfiber and Polypropylene synthetic macrofiber, which can greatly improve their performance when added to concrete or mortar. In this article, TenaBrix, a leading professional concrete fiber manufacturer in China, will give you an in-depth understanding of polypropylene fiber by analyzing the improvement and application of polypropylene fiber to concrete properties.

1. Function

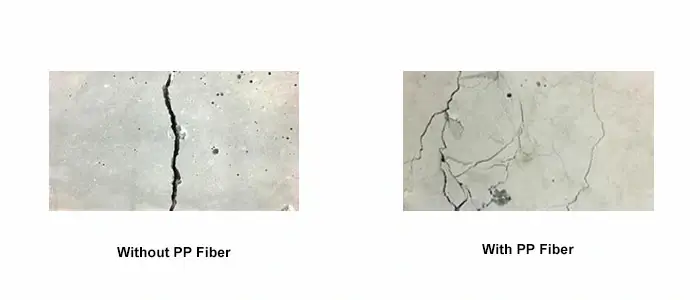

1.1 Anti-crack Function

Polypropylene fibers can effectively reduce the stress concentration at the tip of micro-cracks in concrete, weaken or remove the tensile force caused by dry cracks in concrete or mortar, and prevent the occurrence and development of micro-cracks.

1.2 Improve Anti-infiltration Performance

Evenly distributed fibers form a supporting system, which hinders the surface water analysis and the settlement of aggregates, reduces the bleeding of concrete, reduces the bleeding channels of concrete, and greatly reduces the porosity in concrete so that the impermeability of concrete has improved significantly.

1.3 Improve Anti-freezing and Thawing

Due to the presence of Tenabrix polypropylene fibers in concrete, it can effectively reduce the compressive stress concentration in concrete caused by multiple freeze-thaw cycles, and prevent the further expansion of micro-cracks.

1.4 Improve toughness and Anti-shock

Polypropylene fibers help to absorb the kinetic energy of concrete members when they are impacted. Due to the anti-cracking effect of fibers, when concrete is impacted, the fibers can prevent the rapid expansion of internal cracks, so it can effectively improve the impact resistance and toughness of concrete.

1.5 Improve Durability

The reduction of internal porosity slows down the corrosion and penetration of moisture in the external environment and the erosion and penetration of chemical media, chloride salts, etc., and reduces the damage to the main reinforcement of the structure, so that the durability of concrete is greatly improved and enhanced.

1.6 Improve Fire Resistance

When the internal temperature of the concrete member rises above 165°C, the fiber melts and forms an internal connecting channel for strong high-pressure steam to escape from the interior of the concrete, which can effectively avoid bursting in a fire environment.

2. Application

Adding it to concrete or mortar can effectively control micro-cracks caused by factors such as solid-plastic shrinkage, dry shrinkage, and temperature changes in concrete or mortar. It can be widely used in underground waterproofing projects, roofs, walls, floors, and pools of industrial and civil buildings. , basements, etc., as well as road and bridge work.

As concrete is more and more widely used, fiber has great advantages in improving the performance of concrete such as frost resistance and corrosion resistance, so that concrete can meet the needs of different situations. This article describes the impact on concrete from the function and use of adding Tenabrix polypropylene fibers, ensuring the best performance of concrete, giving full play to the advantages of fiber concrete, and meeting different needs.

For more information about Tenabrix concrete fibers, please contact us.