Concrete has been a fundamental building material for centuries due to its strength, durability, and versatility. However, it is not without its limitations, including cracking, low tensile strength, and susceptibility to impact damage. These weaknesses have led to the development of Fiber Reinforced Concrete (FRC), a composite material that combines the strength of concrete with the toughness of fibers. In this essay, we will explore the benefits of FRC, its manufacturing process, and its applications, with a particular focus on polypropylene fibers from Tenabrix.

Advantages of Fiber Reinforced Concrete

Fiber Reinforced Concrete offers several advantages over conventional concrete. One of the most significant benefits is its ability to control cracking. Concrete is susceptible to cracking due to its low tensile strength and lack of flexibility. However, the inclusion of fibers in the mix creates a network of reinforcement that enhances the ductility and toughness of the material, reducing the likelihood of cracking. Fibers also improve the post-cracking behavior of the material, which means that even after cracking, the FRC maintains some level of load-carrying capacity.

Another benefit of FRC is its impact resistance. The fibers act as a shock absorber, absorbing energy from impact and distributing it across the material. This property is particularly valuable in structures that are vulnerable to impact damage, such as industrial floors, tunnel linings, and bridge decks.

FRC also offers improved durability compared to conventional concrete. The fibers improve the resistance of the material to environmental factors such as freeze-thaw cycles and chemical attack. This increased durability leads to reduced maintenance costs and an extended service life.

Manufacturing Fiber Reinforced Concrete

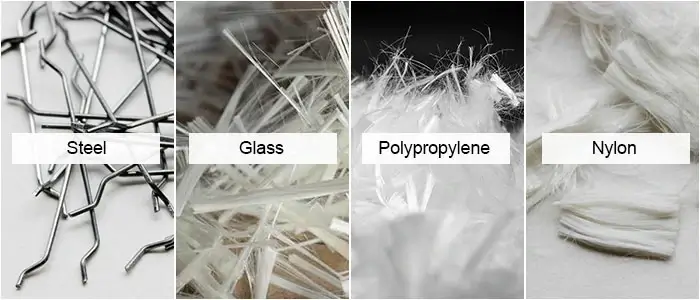

The manufacturing process for Fiber Reinforced Concrete is similar to that of conventional concrete, with the addition of fibers to the mix. The fibers are typically added at a rate of 0.5% to 2.5% by volume of concrete. The type and length of the fibers used can vary depending on the desired properties of the final product. Common fiber materials include steel, glass, polypropylene, and nylon.

Polypropylene fibers are a popular choice for FRC due to their low cost, availability, and ease of use. They are typically supplied in a loose form and added directly to the concrete mix. The fibers are mixed with the other ingredients of the concrete in a drum mixer or a batch mixer. Care must be taken to ensure that the fibers are evenly distributed throughout the mix.

Once the mix is prepared, it is poured into the desired mold or formwork and allowed to cure. The curing time for FRC is similar to that of conventional concrete, typically ranging from 24 to 48 hours. After curing, the FRC is ready for use.

Applications of Fiber Reinforced Concrete

Fiber Reinforced Concrete has a wide range of applications, including in residential, commercial, and industrial settings. One of the most common uses of FRC is in the construction of industrial floors. These floors are subjected to heavy loads, impact damage, and abrasion, and require a high level of durability and strength. FRC is an ideal material for these applications due to its ability to resist cracking, impact, and wear.

Another common use of FRC is in the construction of precast concrete products, such as pipes, panels, and beams. These products require high strength and durability to withstand the stresses of transportation and installation. FRC provides these properties, reducing the risk of damage during handling and assembly.

Fiber Reinforced Concrete is also used in the construction of tunnels and underground structures. These applications require a high level of resistance to impact and seismic loads, as well as protection against water infiltration. FRC is an ideal material for these applications due to its toughness, durability.

Polypropylene fibers are a popular choice for Fiber Reinforced Concrete, and Tenabrix is a leading supplier of these fibers. Tenabrix polypropylene fibers are made from high-quality materials, ensuring consistent performance and reliability. The fibers are available in various lengths and diameters, making them suitable for a wide range of FRC applications.

Tenabrix polypropylene fibers are compatible with all types of concrete mix designs and can be used in both wet and dry-mix shotcrete applications. They are suitable for a wide range of FRC applications, including industrial floors, precast concrete products, tunnel linings, and bridge decks.

Conclusion

In conclusion, Fiber Reinforced Concrete is an ideal material for applications that require high strength, durability, and resistance to impact and wear. Polypropylene fibers from Tenabrix are an excellent choice for FRC, providing consistent performance and reliability. As a supplier of these fibers, Tenabrix is committed to providing high-quality materials and excellent customer service to ensure the success of its customers’ projects.