Concrete is one of the most important building materials in the world. From roads and bridges to buildings and tunnels, it supports almost every modern structure. However, traditional concrete has one major weakness: it is strong in compression but weak in tension. This means it can crack easily when exposed to pulling forces, temperature changes, shrinkage, or heavy loads.

To solve this problem, engineers developed Fiber Reinforced Concrete (FRC). By adding small fibers into the concrete mix, the material becomes tougher, more flexible, and more durable. These fibers act like tiny “reinforcing bars” that spread throughout the concrete, holding it together when cracks begin to form.

Today, fiber reinforced concrete is widely used in industrial floors, pavements, tunnels, bridges, precast elements, and architectural structures. In this article, we will first look at the main types of fiber reinforced concrete, then explore the top 7 benefits of fiber reinforced concrete, explained in simple and practical terms.

Main Types of Fiber Reinforced Concrete

Different fibers offer different advantages. Choosing the right type depends on the project environment, load conditions, and budget.

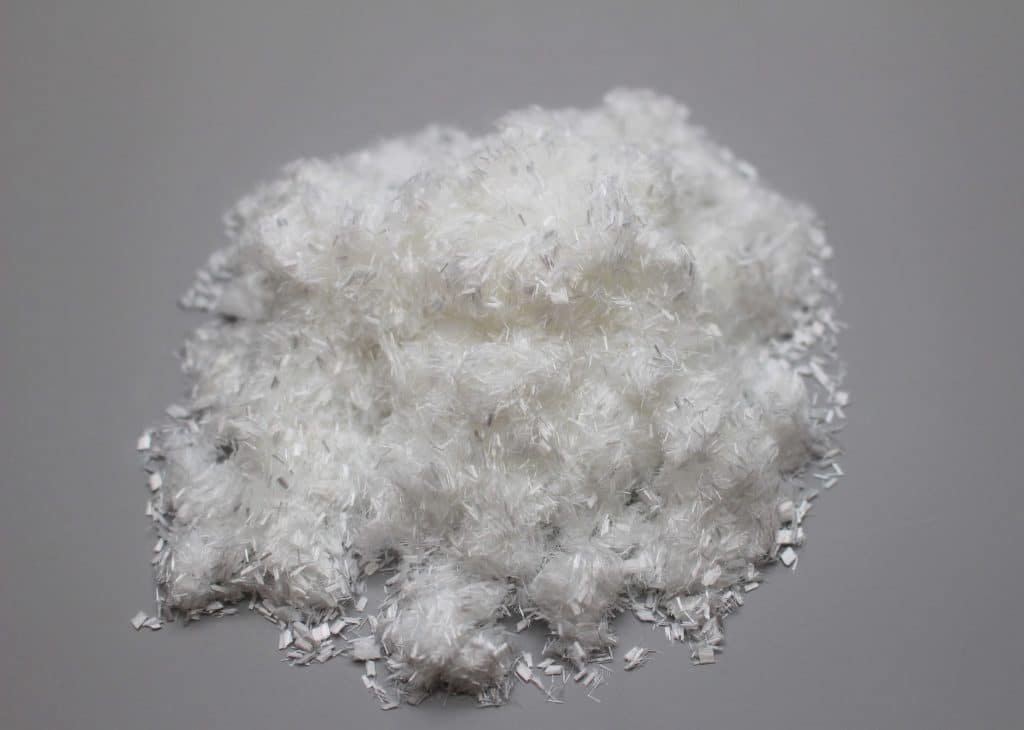

1. Polypropylene (PP) Fiber Reinforced Concrete

PP fibers are lightweight synthetic fibers that are widely used to control early-age cracking. They help reduce plastic shrinkage and drying shrinkage cracks, especially in slabs, pavements, and overlays.

Another important benefit of PP fibers is that they do not corrode and have low thermal conductivity. This means they can improve heat resistance and provide a certain level of insulation, which is helpful in fire-prone or high-temperature environments.

2. Polyester Fiber Reinforced Concrete

Polyester fibers are durable, light, and resistant to corrosion. Unlike steel, they do not rust, making them suitable for humid or chemically aggressive environments.

They also improve tensile, flexural, and compressive strength, which makes concrete more resistant to heavy loads and repeated stress. Polyester fibers are commonly used in precast components, thin wall panels, and repair mortars.

3. Steel Fiber Reinforced Concrete (SFRC)

Steel fibers are the strongest and most widely used fibers for heavy-duty applications. They greatly improve impact resistance, fatigue performance, and crack control.

In many industrial floors, tunnels, airport runways, and bridges, steel fibers can partially replace traditional reinforcement bars, simplifying construction and improving long-term performance.

4. Polyvinyl Alcohol (PVA) Fiber Reinforced Concrete

PVA fibers have excellent tensile strength and bonding ability with cement. They can effectively bridge micro-cracks and stop them from spreading.

Because of their ability to control fine cracks and improve surface quality, PVA fibers are often used in architectural panels, interior precast elements, and decorative concrete.

5. Glass Fiber Reinforced Concrete (GFRC)

Glass fibers are lightweight, non-corrosive, and cost-effective. They also have good resistance to alkaline environments in concrete.

GFRC is widely used for architectural cladding, decorative panels, and thin structures where traditional steel reinforcement is difficult to use. It allows designers to create complex shapes while maintaining strength and durability.

Top 7 Benefits of Fiber Reinforced Concrete

1. Excellent Crack Control and Higher Tensile Strength

One of the biggest advantages of fiber reinforced concrete is its ability to control cracks. When concrete is under tension, small cracks can appear very quickly. Fibers act like tiny bridges across these cracks, holding the concrete together and slowing down crack growth.

This “bridging effect” improves tensile strength and helps the structure stay intact even under dynamic loads such as earthquakes, vibrations, or traffic loads. Instead of one large crack, the stress is distributed into many tiny cracks, making the structure safer and more reliable.

In simple words, fiber reinforced concrete does not stop cracks completely, but it makes them smaller, fewer, and much less dangerous.

2. Improved Durability and Fatigue Resistance

Many structures experience repeated loads every day. Roads carry vehicles, bridges carry traffic, and industrial floors carry heavy machines. Over time, this repeated stress can cause concrete to weaken and fail.

Fibers help concrete resist this “fatigue damage.” They prevent surface peeling, reduce internal damage, and slow down material degradation. This significantly increases the service life of the structure.

For projects that must perform reliably over many years, such as highways, tunnels, and factory floors, fiber reinforced concrete is an excellent choice.

3. Better Resistance to Water, Freeze-Thaw, and Chemicals

Durability is not only about strength. It is also about how well concrete can resist harsh environments.

Fiber reinforced concrete has improved resistance to:

- Water penetration

- Freeze-thaw cycles

- Chemical attack

- Salt and moisture damage

By limiting crack width, fibers reduce the pathways for water and harmful chemicals to enter the concrete. This protects internal reinforcement and prevents long-term deterioration.

In cold regions, where freeze-thaw damage is a major problem, fiber reinforced concrete performs especially well because it limits micro-cracking caused by ice expansion.

4. Strong Mechanical Performance and High-Temperature Stability

Fibers increase both the strength and toughness of concrete. Toughness means the material can absorb more energy before failing. This is very important for structures exposed to impact, vibration, or sudden loads.

Some fibers, such as steel and PP fibers, also improve performance under high temperatures. PP fibers, in particular, can reduce internal vapor pressure during fire exposure, which lowers the risk of explosive spalling.

This makes fiber reinforced concrete safer for tunnels, underground facilities, and fire-sensitive structures

5. Cost-Effective Over the Entire Life Cycle

Fiber reinforced concrete offers strong economic value when looking at the whole life cycle of a project. Although the initial cost may be slightly higher, it can significantly reduce overall expenses in the long run.

During construction, fibers can replace part of the traditional reinforcement, simplifying installation and reducing labor time and costs. The construction process becomes faster and more efficient.

After completion, its excellent crack control and durability mean fewer repairs and lower maintenance needs. Structures last longer and remain in better condition, which saves money over time.

Overall, fiber reinforced concrete is a smart investment that balances upfront cost with long-term savings.

6. Wide Adaptability and Broad Application Range

Fiber reinforced concrete is highly adaptable because different types of fibers can be chosen according to specific project needs. Whether it is steel fibers for heavy loads, polypropylene fibers for crack control, or glass and PVA fibers for architectural applications, each option provides targeted performance benefits.

Thanks to this flexibility, fiber reinforced concrete is used in a wide range of projects, including industrial floors, roads and bridges, tunnels, precast components, underground structures, and hydraulic engineering. It works equally well in structural and decorative applications.

This wide applicability makes fiber reinforced concrete a practical and versatile solution for modern construction.

7. Environmentally Friendly and Sustainable

Fiber reinforced concrete supports green construction in several ways:

- Reduced use of steel reinforcement

- Longer service life

- Less frequent repairs

- Lower material waste

- Lower energy consumption over time

By controlling cracks and increasing durability, fiber reinforced concrete minimizes resource consumption and reduces carbon emissions related to cement, steel, and maintenance activities.

From a sustainability perspective, it is a smart solution that aligns with modern green building goals.

Applications of Fiber Reinforced Concrete

1. Transportation Engineering

Fiber reinforced concrete is widely used in airports, ports, roads, and bridges, where high durability and load-bearing capacity are essential. Its ability to control cracks and resist heavy traffic makes pavements, runways, and bridge decks more durable and long-lasting. By reducing maintenance needs, it ensures safer and more reliable infrastructure.

2. Pipeline Engineering

In pumping stations, sewage systems, and water treatment facilities, fiber reinforced concrete strengthens pipes and other structures against internal pressure and environmental challenges. The added fibers improve durability and reduce the risk of damage from corrosion or mechanical stress, ensuring pipelines remain safe and functional for longer periods.

3. Underground Engineering

Tunnels, subway stations, and other underground facilities face significant ground and water pressures. Fiber reinforced concrete improves structural stability, limits cracking, and enhances safety. Fiber-reinforced shotcrete is commonly used in these applications, providing reliable support while simplifying construction in challenging underground conditions.

Fiber reinforced concrete is also widely applied in high-rise buildings, large public structures, and architectural projects. Its versatility allows it to enhance both structural performance and aesthetic design, making it a preferred material in modern construction.

Real Project Example: Shanghai Expo France Pavilion

A famous example of fiber reinforced concrete is the France Pavilion at the Shanghai World Expo. The building’s exterior used Glass Fiber Reinforced Concrete (GFRC) to create a white, grid-like façade.

This GFRC structure:

- Improved wind and earthquake resistance

- Offered higher compressive and bending strength than ordinary concrete

- Allowed a thin, lightweight, and smooth surface

- Enhanced architectural beauty and design freedom

It proved that fiber reinforced concrete is not only strong but also highly suitable for creative architectural designs.

Conclusion

Fiber reinforced concrete is a versatile and powerful upgrade to traditional concrete. By adding fibers, it transforms a brittle material into one that is stronger, tougher, and more durable, capable of withstanding cracks, heavy loads, and harsh environmental conditions.

The top benefits—improved crack control, enhanced durability, better mechanical performance, long-term cost savings, broad adaptability, and environmental friendliness—make fiber reinforced concrete an ideal choice for modern construction. From industrial floors and bridges to tunnels and architectural designs, it provides both structural reliability and aesthetic flexibility.

With its combination of strength, longevity, and sustainability, fiber reinforced concrete is shaping the future of construction, offering smarter, safer, and more efficient solutions for a wide range of projects.